Erweiterung der MRT Thomson-East Coast Line in Singapur

The Thomson-East Coast Line is a future MRT line in Singapore that will connect the Thomson Line with the Eastern Region Line. The 43-km link will add 31 new stations to the existing rail network, with seven interchange stations.

For that project, Dextra supplied numerous packages, including Marine Terrace Station, where four large-diameter Weiche Augen were installed in the diaphragm wall cages in August 2017.

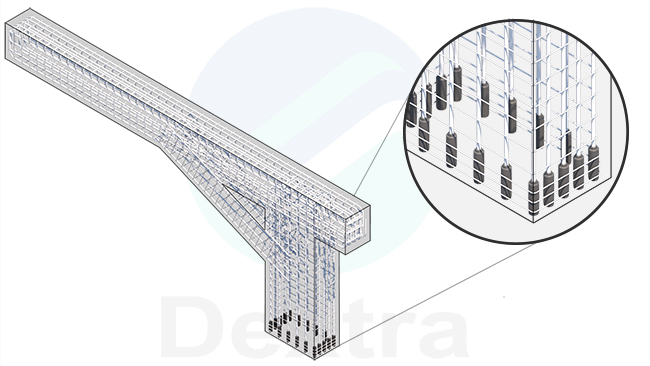

Soft-Eyes are made of GFRP rebar, which is used to replace the steel reinforcement in the D-Walls of construction shafts. When the Tunnel Boring Machine (TBM) breaks through the D-Walls, it easily cuts the GFRP bars, saving time in the project schedule and reducing equipment costs.

Dextra pioneered this application in the Bangkok metro project in 1998 and has extensive experience in the in-house design and manufacturing of Soft-Eyes.

The D-Walls installed at Marine Terrace Station also feature Bartec® rebar couplers, a common solution for reconnecting slabs horizontally in underground stations. Bartec couplers are also widely used for vertical connections in foundation piles and slabs.