Time flies and construction projects are going strong in the United Arab Emirates. This February 2018, Dextra is celebrating 15 years of operations in Dubai, our Middle East regional hub that started Dextra expansion in the region. This is a true success story embedded in the concrete of the most famous landmarks in the Middle East!

Dextra Midde East, Dextra first entity in the Gulf, has grown to become a leading provider of technical solutions for the construction sector in the region, participating to most of challenging infrastructure and supertower projects. We would like to thank to all the customers, users, prescriptors which have been using Dextra products across the years.

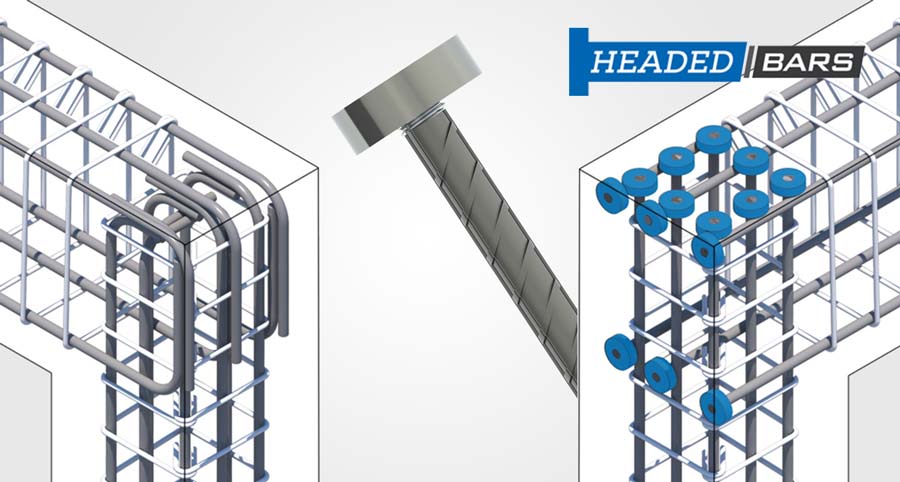

Leader in reinforcement splice and equipment in the Middle East

Our concrete reinforcement solutions in the Middle East are distributed through a strong network of cut & bend distributors located across 6 countries. We would like to give them a very special “Thank you” as our success in the Gulf is also theirs!

Made-to-order systems for large construction projects

For Dextra other two construction business lines, Engineered Bar Systems and Ground Engineering solutions, Dextra distributes directly its taylor-made solutions to local and international contractors in the region.

Our typical projects include infrastructures like ports, oil & gas terminals, airports, bridges and flyovers but also large building such as shopping centers.

As we already prepare the next 15 years, Dextra solutions started embracing the innovations that will make the productive construction industry of tomorrow, including precast and the digital BIM revolution.

All the team across the Middle East is looking forward to meeting you soon to discuss with you the amazing projects that will create the Middle East of the next 15 years!

Contact our Dubai team