بناء مستقبل أقوى: مجموعة Dextra وSilva Global تتعاونان لدفع الأعمال في قطاعي البنية التحتية والبناء في أستراليا

في خطوة استراتيجية تهدف إلى تعزيز تجربة العملاء وتقديم حلول فريدة من نوعها، أعلنت مجموعة Dextra Group، الشركة العالمية الرائدة في الحلول الهندسية، عن شراكتها مع Silva Global، الموزع المحلي البارز ومزود الحلول في أستراليا. يمثل هذا التعاون علامة فارقة مهمة لمجموعة Dextra، حيث تحتفل بالذكرى الأربعين لتأسيسها هذا العام. وستركز الشراكة بشكل خاص على قطاعات البنية التحتية والبناء في أستراليا، حيث تجمع بين الخبرة الهندسية لمجموعة Dextra Group والفهم العميق لشركة Silva Global والتفاعل مع متطلبات السوق المحلية.

ميزة الشريك المحلي: إبراز خبرة لا مثيل لها في المقدمة

وسيلعب الحضور المحلي القوي لشركة Silva Global ومعرفتها الواسعة بالسوق الأسترالية دورًا محوريًا في نجاح الشراكة. ويهدف التحالف إلى الاستفادة من قدرة سيلفا على الاستجابة بسرعة وكفاءة، وضمان تقديم الخدمة السريعة التي تلبي المتطلبات الصعبة للصناعة. بالإضافة إلى ذلك، فإن مخزون Silva Global الشامل سيمكن من الوصول السريع إلى المنتجات، مما يقلل من المهل الزمنية ويضمن إكمال المشاريع في الوقت المناسب. علاوة على ذلك، ستدمج الشراكة مبادئ هندسة القيمة، وتقدم حلولاً فعالة من حيث التكلفة مصممة خصيصًا لتلبية الاحتياجات المحددة للعملاء في قطاعي البنية التحتية والبناء.

حلول المنتجات المتطورة لتحسين الأداء

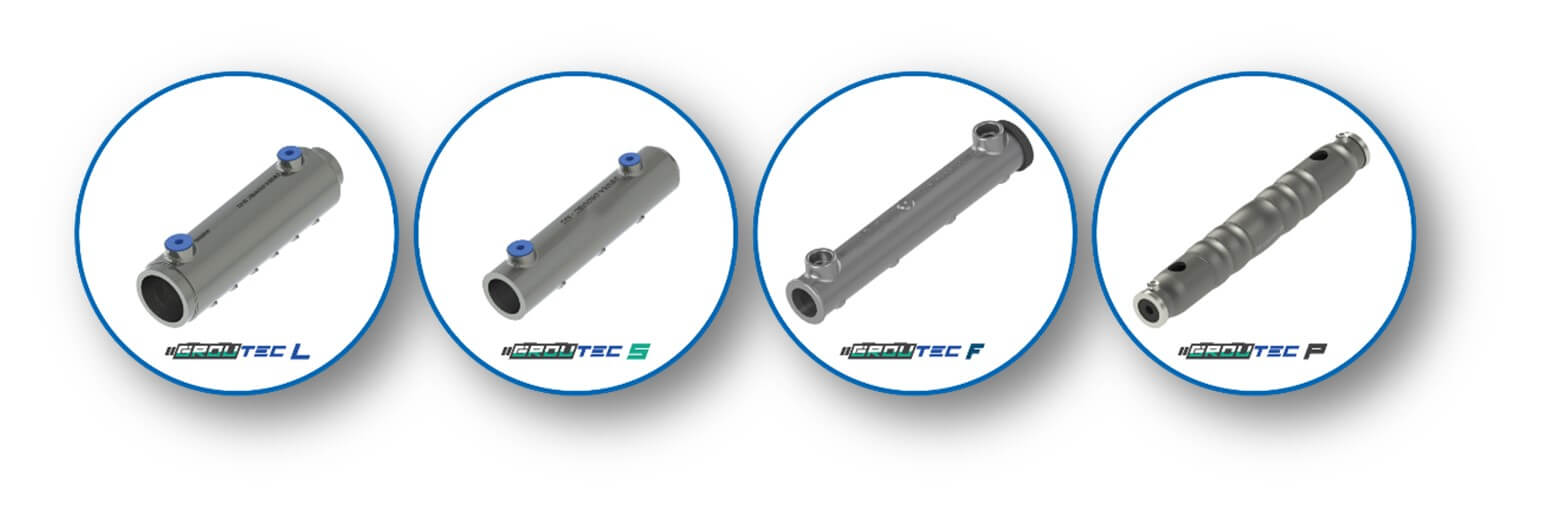

وكجزء من التعاون، ستعمل Silva Global كشريك مزود الحلول لأستراليا، حيث ستقدم أنظمة الوصلات الميكانيكية، وقارنات Griptec وGroutec، بالإضافة إلى مجموعة منتجات Dextra’s Structural Bar مثل أنظمة ما بعد الشد والقضبان المعمارية إلى السوق المحلية. . تضمن شركة Griptec، المعروفة بتطبيقاتها النووية، السلامة الهيكلية للوصلات الخرسانية، بينما توفر شركة Groutec حلولاً موثوقة ودائمة للتطبيقات مسبقة الصب. وستمكن هذه المنتجات المبتكرة العملاء الأستراليين من تحسين جودة وكفاءة واستدامة مشاريعهم، مما يضعهم في طليعة التطورات الصناعية.

التميز الذي يركز على العملاء: تمكين النجاح

من خلال الالتزام المشترك بإرضاء العملاء، تعطي Dextra Group وSilva Global الأولوية للخدمة الاستثنائية والمساعدة السريعة والخبرة الفنية. ومن خلال الحفاظ على مخزون قوي من المنتجات عالية الجودة، ستعمل الشراكة على تعزيز إمكانية الوصول للعملاء، مما يضمن حصولهم على وصول سريع وموثوق إلى المواد التي يحتاجونها لمشاريعهم. ومن خلال الاهتمام الشخصي والحلول المخصصة، تهدف Dextra Group وSilva Global إلى تمكين العملاء من تحقيق أهدافهم بكفاءة وفعالية.

الفوائد التي تعود على العملاء وأصحاب المصلحة: تحقيق نتائج استثنائية

يتيح التعاون بين Dextra Group وSilva Global للعملاء إمكانية الوصول إلى أحدث التقنيات والحلول المبتكرة التي من شأنها تحويل مشاريعهم. ومن خلال الاستفادة من مجموعة منتجات Dextra Group عالية الجودة والحضور المحلي والقدرات التقنية لشركة Silva Global، يمكن للعملاء تحقيق أهداف مشروعهم بشكل أسرع مع تقليل البصمة البيئية. تعمل الشراكة أيضًا على تبسيط إدارة المشروع، مما يضمن التنفيذ السلس والتحكم في التكاليف والتسليم في الوقت المناسب. يمكن للعملاء أن يتوقعوا نهجا شاملا ومتكاملا يتجاوز توقعاتهم ويحقق نتائج استثنائية.

مع استمرار تطور قطاعات البنية التحتية والبناء في أستراليا، تستعد شراكة Dextra Group وSilva Global للعب دور حاسم في دفع التقدم وتعزيز النمو المستدام. ومن خلال رؤية مشتركة للتميز والالتزام بإرضاء العملاء، سيعيد هذا التحالف تشكيل الصناعة من خلال تقديم حلول متقدمة وخدمة فعالة ومنتجات رائدة.

حول مجموعة ديكسترا:

Dextra Group هي شركة عالمية رائدة مشهورة في مجال الحلول الهندسية، حيث تقدم أحدث التقنيات والمنتجات المبتكرة لمختلف الصناعات. مع إرث فخور يمتد إلى 40 عامًا، تلتزم مجموعة Dextra بتوفير قيمة استثنائية وتميز في جميع مساعيها مع الحفاظ على الاستدامة في قلب جميع أنشطتنا.

https://www.dextragroup.com/

حول سيلفا العالمية:

Silva Global هي موزع محلي موثوق به متخصص في توريد المواد والمنتجات لصناعة البناء والتشييد. بفضل شبكة واسعة وفهم عميق للسوق الأسترالية، تقدم Silva Global خدمة سريعة وحلول استثنائية للعملاء في جميع أنحاء البلاد.

https://silva-global.com/