Tunneling and Mining

Typical Applications

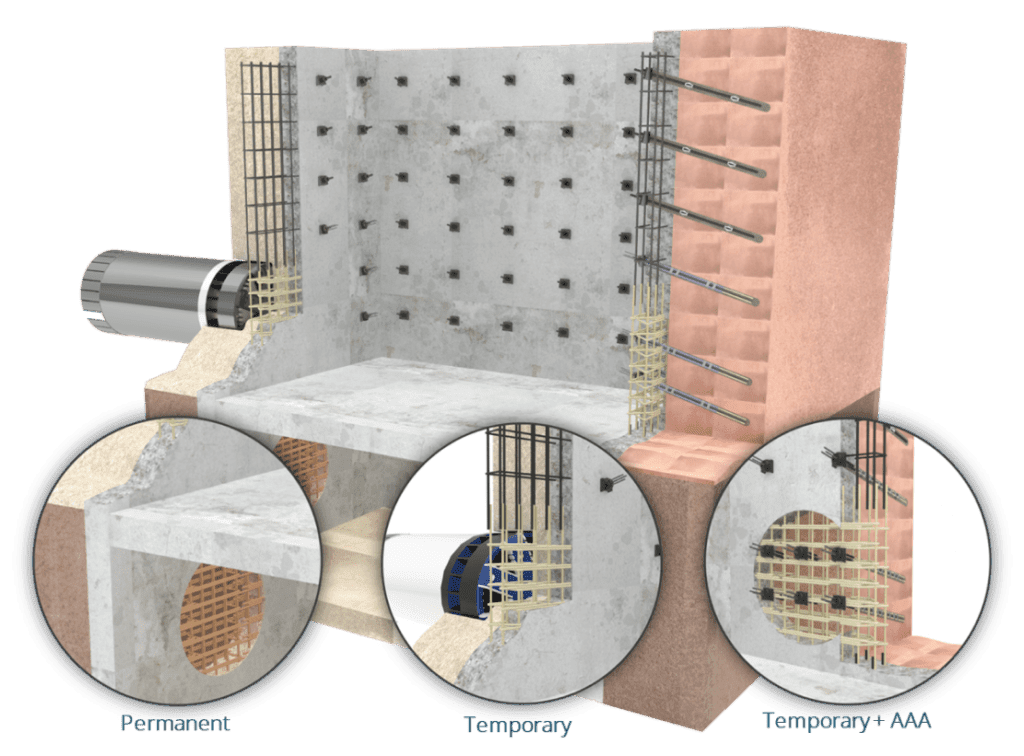

For roof and wall bolting in both temporary and permanent applications

Our Solutions

GEOTEC lattice girder systems are lightweight, three-dimensional curved steel frames that are composed of main bars, secondary bars, connection plates, footplates, and stiffeners.

The lattice girder can provide immediate support for tunneling environments.

The radius of the bending is tailor-made to meet each project’s demands.

Umbrella Pipe

A pre-support system for weak grounds

GEOTEC™ umbrella pipe system is a pre-support in soft and weak ground conditions. The system comprises steel pipes installed from the tunnel face to form a roof to stabilize the tunnel headings. Distributing the load in the longitudinal direction can decrease deformation during excavations.

The supporting mechanism of the umbrella pipe method is to stabilize the excavation face in both the transverse and longitudinal directions by an arch-like reinforced zone. The support system can be divided into three different aspects:

Radial support Longitudinal support

Subdivision of open areas of the unsupported zone

Steel Combination Bolt

Drilling, grouting, and anchoring, in one!

GEOTEC Steel self-drilling rock bolt is a rock-bolting system based on a fully coarse threaded hollow bar.

It is especially recommended for the following applications:

Roof and wall bolting.

All ground conditions. GEOTEC self drilling rock bolts do not require pre-drilling a hole, therefore making it usable even in soft rock conditions.

Installation with grout. The hollow steel anchor rod also acts as a grouting pipe to ease setup. For non-grouting applications, please refer to the mechanical anchor or expandable friction bolt.

Temporary or permanent applications. With optional epoxy coating available for permanent applications.

ASTEC FRP hollow rock bolt is a rock-bolting system based on fully threaded hollow GFRP bars. It is specially designed for the following applications:

Face-bolting and temporary applications: The cut-ability of FRP makes it the ideal solution for face bolting or any other tunneling/mining application where further excavation is required.

Cohesive soil & hard rock conditions: ASTEC is inserted into a pre-drilled hole. For a non-cohesive soil environment, refer instead to FRP Self-Drilling Bolts.

Installation with grout: The hollow GFRP anchor rod also acts as a grouting pipe to ease installation.