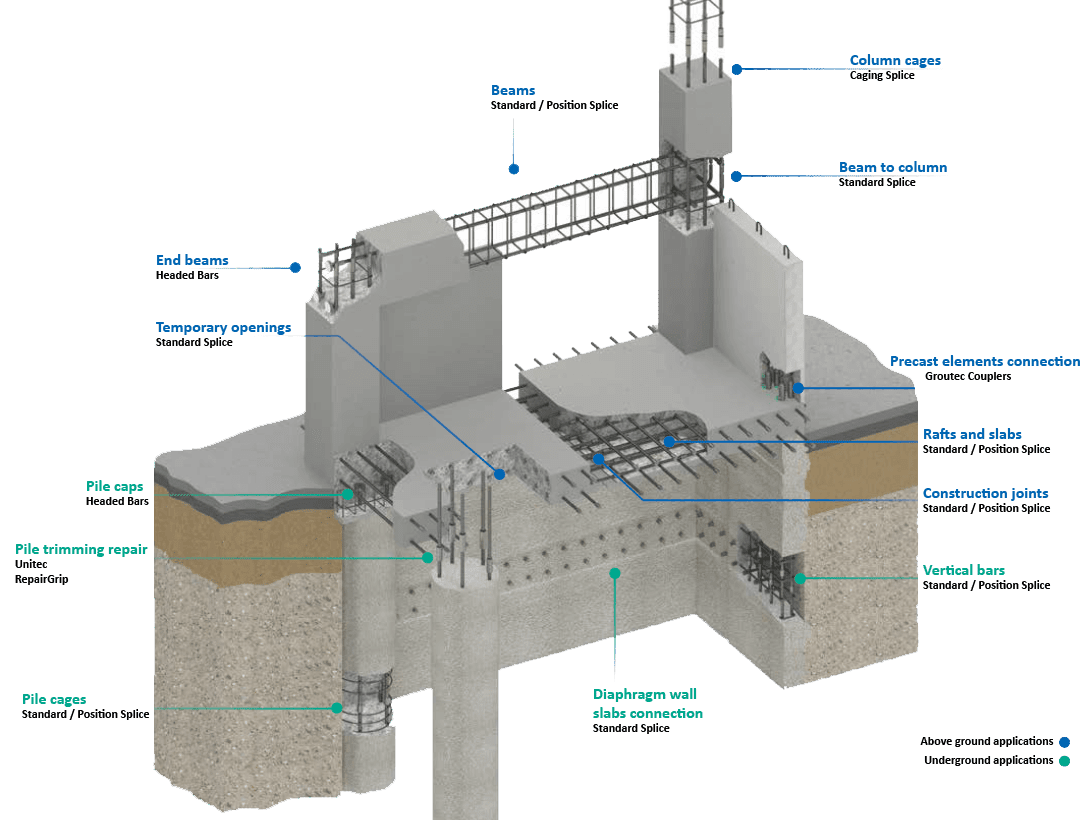

Cast-in-Place

Typical Applications

With rebar couplers, columns can be cast to their full height, resulting in a faster construction cycle.

Without couplers, a lap length is required for continuation bar connections. The formwork must be custom-made with holes for the rebars, which often leads to concrete leakage.

Couplers not only eliminate unnecessary rebar costs and reduce rebar wastage by up to 10%, but they also reduce rebar congestion at lap areas.

Couplers help maintain the load path and structural integrity, while also reducing the cost associated with the overlap length of rebar.

Bending and unbending the bars requires more tools and may increase the risk of bar breakage. Couplers make the installation of continuation bars easier.

To connect pre-fabricated cages, caging couplers offer a more flexible and faster method than traditional bar welding.

The use of couplers results in a faster construction cycle and more efficient rebar connections.

When space is limited on the project site for installing a tower crane for high-rise construction, an opening in the floor slabs is required. By leaving bridging couplers inside the slabs, reconnection becomes easier and more time-efficient.

Our Solutions

Bartec® / Fortec® is a parallel threaded mechanical splicing system designed for the connection of concrete reinforcing bars from Ø12 to 50 mm (ASTM #4 to #18).

Bartec® / Fortec® couplers are designed and manufactured in compliance with Eurocode 2, BS 8110, DIN 1045, ACI 318, IBC, AASHTO, ASME Sec III Div 2.

Bar-end Preparation Equipment

Every connection is 100% tested

One

Operator

30-40 Seconds

Per bar-end

One operator, one machine

Light and productive rebar coupler solution.

This splicing system based on cold-rolled parallel threads requires only a single machine and a single operator for its rebar preparation. Like all Dextra splicing systems, Rolltec® offers the full range of splice solutions (standard, position, transition, caging) and covers a large range of both metric and imperial measurements.

2 steps process

Peeling

Thread Rolling

As a corrosion-free alternative to steel rebar, Dextra has been a leader in the composite industry for the past 25 years, manufacturing high-quality FRP solutions for large infrastructure projects.

The company excels in providing comprehensive solutions to its customers, with expertise in designing concrete structures reinforced with GFRP rebars.

All Durabar™ GFRP rebars are produced in Dextra’s ISO-9001 and ISO-14001 certified factories in China and India, following the company’s strict quality assurance policy.